nieuws detail

Dual Milestone for Toyota Material Handling with Orangeworks as partner

A unique moment earlier this week where Toyota Material Handling and Orangeworks have reached a dual milestone in their cooperation. Since 1992 Orangeworks, in these days ‘Staalwerk’ and Toyota Material Handling are intensively cooperating with engineering and production of a special product for the food industry.

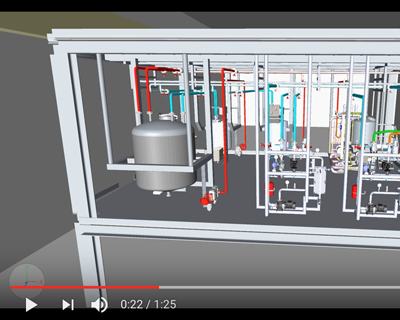

Animation vertical start up approach

Via the link below we provide a video explaining the Orangeworks vertical startup approach.

Orangeworks won FD Gazellen Award

Orangeworks finished in 6th place, on the 24th of November at the FD Gazellen awards South Netherlands in the category big! Also top-scoring as company for the manufacturing industry.

Orangeworks goes USA

Illinois is at the heart of the American food industry. We like to get close to that as Orangeworks. The realization of this ambition is now a little closer through the collaboration with a overseas partner, Spec Engineering, from Chicago.

Partnership Actemium & Orangeworks

Orangeworks and Actemium’s cooperation goes back many years. During the last three years both companies have intensified their worldwide collaboration. This has yielded a very good relationship. However, the question was raised how we could establish a partnership from which our customers can benefit even more.

A look behind the scenes of vertical startups

Last March, Orangeworks and Actemium jointly hosted a well-attended client event at the Orangeworks location in Mill [NL]. Managers from the food, feed and beverage industries were informed about a specific project method: the Vertical Start Up Approach.

New facilities for Orangeworks: "Even more room for creativity and craftsmanship"

After having been based in Mill, The Netherlands for almost 50 years and 30 years in Veghel, a new era is beginning for Orangeworks. At the start of November 2018, the construction of a new location in Oss has started at the Vorstengrafdonk business park. "Working more efficiently, more knowledge exchange, room for growth and excellent accessibility: we could not say no to that."

No concession to safety

“We try to lead the way in safety,” says Jan de Wringer, owner of Orangeworks, without hesitation. Both necessity and pride go hand in hand here. “We have an extensive safety culture and we are constantly working on it. Not only when it comes to our own employees, but certainly also for our - mostly international - customers.”

"We want to bring value to our customers"

Although Pim Bos and Gert-Jan Langen only recently joined forces with the Orangeworks sales team, their names will already ring a bell with many customers. Their motive? “We do not want to sell machines, we want primarily to help our customers and solve their issues. That's why we get out of bed in the morning.”

Your wastewater is worth money

"By analyzing value streams from waste water, companies can make a profit on multiple fronts." With a simple calculation, Willem Tomassen shows that it is smart to critically view the management of waste water. Incidentally, not only because of the financial benefits, but also with a look at the environment and the future.

New syrup cooker system for the Banketgroep

Soon the current syrup cooker of the Banketgroep will be replaced by an innovative installation of Orangeworks. Thanks to an intensive and efficient cooperation between the two companies, the project has a short lead time. "We really do it together."

12.5-year jubilee Paul Selten: I enjoy going to work every day.

With satisfaction Paul closes the door behind him; his workday is finished. "Tomorrow is another day!" he says enthusiastically. After 12,5 years at Orangeworks he still enjoys working here every day. "No two days have been the same. My work is very diverse and I have always been given the opportunity to grow. "After a number of instructive years, various courses and training, Paul is now working as a projectplanner. Because of his experience, he knows what needs to be done to make production run smoothly. "My last project was for a manufacturer of filled chocolates in Egypt; a challenging job with a tight schedule, that makes the work interesting. The days and years fly by here”.

Minimizing the impact of production stops thanks to spare parts

Downtime is never desired let alone when it is unscheduled. The problems that arise as a result are increased if there is no adequate stock of spare parts. That is why a project for Orangeworks is only complete with the offering of a complete, well thought-out spare parts list. “Thanks to our approach, customers can quickly resume work.”

Improved food safety and less waste through worldwide upgrade

The best possible food safety and minimum residual waste during the production process. In line with their worldwide standard and with guaranteed quality. That was the wish of an international food manufacturer. Orangeworks accepted the challenge and started the "filter skid" project in the summer of 2018, for which even the factory was partly converted. "This way we work efficiently and we can keep costs down."

Flexible workmethods Orangeworks enable fast delivery

Building two heater weldments of more than 8 meters in height within 6 weeks is a challenge Orangeworks wanted to tackle eagerly. Frank Appeldoorn proudly tells about the start of the extensive project that Orangeworks has managed to bring to a good end thanks to flexibility and enthusiasm.

Family man, assisting foreman and mentor Jos van der Wijst: 'Every project is different at Orangeworks.'

Jos enjoys working at Orangeworks for over 12,5 years now. Jos: “One of my biggest drivers is the variety in activities involved in the daily work. Because we make customized solutions for our customers, no project is the same. ” In the spring of 2006, Jos started a new chapter in his life. After he had to close his own company due to a difficult market, he took a next step in his career at Orangeworks. The years have flown by and during this time Jos has also, in addition to his work as assisting foreman, guided several colleagues during their training as a craftsman.

Reduced raw material consumption and increased insight through process optimization

Duyvis, part of multinational PepsiCo since 2006, aspired to optimize their production line already for a while; reducing the weekly consumption of sunflower oil and gaining insight in the sunflower oil consumption per production line. With this goal in mind Duyvis found their partner in Orangeworks and Actemium.

Orangeworks acquires Tanis Food Tec: joining forces for the food industry

This year we have the honour of celebrating two special occasions in Oss, the Netherlands. Orangeworks, manufacturer of machinery and production equipment for food processing companies worldwide, is commemorating its 50th anniversary. In addition, it has been announced that the company is set to acquire Tanis Food Tec (TFT) as of 12 June this year.

Mirjam van Dijk appointed as CCO Orangeworks group and Director TFT Lelystad

It is with great pleasure that we can inform you that Orangeworks group has appointed Mirjam van Dijk as CCO Orangeworks group and Director TFT Lelystad. Mirjam van Dijk brings over 25 years of experience and knowledge in the global process technology and production and engineering industry. With her innovative leadership and her global network in the industry she will join the team of Orangeworks and TFT to help deliver the international growth ambition of the group.

VADO expands position in the food industry through acquisition of Orangeworks

Eindhoven, 11 October 2022 – Long-term investment company VADO Beheer has acquired Orangeworks (Oss, the Netherlands). Orangeworks develops and produces high-quality process installations and production equipment for numerous renowned FMCG producers worldwide. With this takeover, VADO further expands its position in mechanical engineering for the food industry.

Press release - When Creams and Marshmallows meet Chocolate

Böhnke & Luckau technology acquired by Orangeworks

Wernigerode, Germany - Oss, Netherlands – May, 2024 – Orangeworks, a global leader in confectionery food processing technology, is excited to announce its acquisition of Böhnke & Luckau technology (B&L Chocolates), a respected name in chocolate machinery industry. This strategic move comes four years after Orangework's successful acquisition of Tanis Food Tec, reinforcing its commitment to driving innovation and excellence in the confectionery sector.

Orangeworks Group closes strategic alliance with S&S Baking Solutions

Orangeworks Group, leading developer and supplier of advanced technologies for the food industry, has signed a strategic partnership with S&S Baking Solutions. With this alliance, both companies focus on jointly further developing innovative, sustainable and efficient production technologies for the baking industry worldwide.